ਬਲੌਗ

-

ਚੀਨ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡ ਕੰਪਨੀ

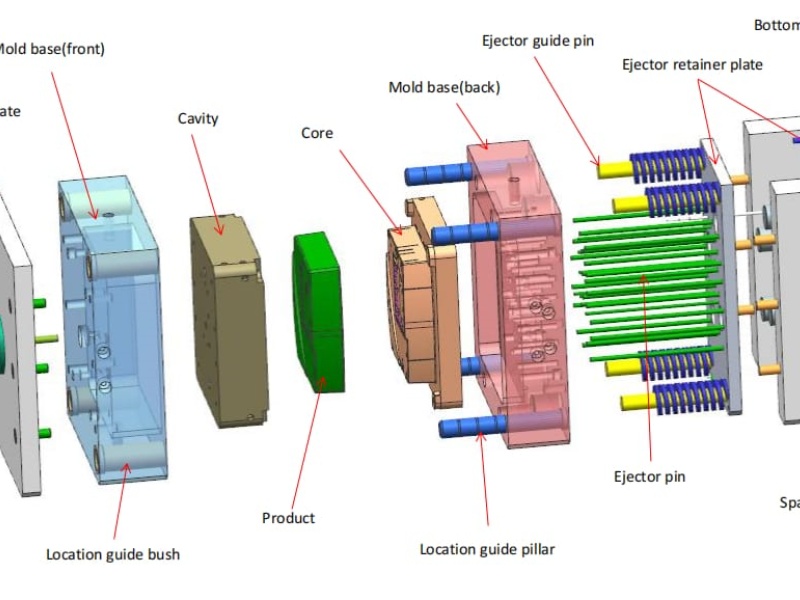

ਅੱਜ ਕੱਲ੍ਹ ਪਲਾਸਟਿਕ ਦੇ ਸਮਾਨ ਦੀ ਵਰਤੋਂ ਪੂਰੀ ਤਰ੍ਹਾਂ ਨਾਲ ਸਾਡੀ ਜ਼ਿੰਦਗੀ ਹੈ, ਘਰੇਲੂ ਜਾਂ ਉਦਯੋਗਿਕ ਵਿੱਚ ਜੋ ਵੀ ਹੋਵੇ।ਪਰ ਕੀ ਤੁਸੀਂ ਸੱਚਮੁੱਚ ਜਾਣਦੇ ਹੋ ਕਿ ਪਲਾਸਟਿਕ ਦਾ ਹਿੱਸਾ ਕਿਵੇਂ ਬਣਾਉਣਾ ਹੈ?ਪੜ੍ਹਦੇ ਰਹੋ, ਇਹ ਲੇਖ ਤੁਹਾਨੂੰ ਦੱਸੇਗਾ।ਇੰਜੈਕਸ਼ਨ ਮੋਲਡ ਕੀ ਹੈ ...ਹੋਰ ਪੜ੍ਹੋ -

ਉਦਯੋਗਿਕ ਪਲਾਸਟਿਕ ਪੁਰਜ਼ਿਆਂ ਦਾ ਪ੍ਰੋਫੈਸ਼ਨਲ ਕਸਟਮਾਈਜ਼ੇਸ਼ਨ ਨਿਰਮਾਤਾ

Ruicheng ਇੰਜੈਕਸ਼ਨ ਮੋਲਡਿੰਗ ਉਦਯੋਗਿਕ ਹਿੱਸੇ ਦੇ ਨਿਰਮਾਣ ਵਿੱਚ ਇੱਕ ਮਾਹਰ ਹੈ.ਸਾਡੀਆਂ ਕੁਸ਼ਲ ਅਤੇ ਸਟੀਕ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡਿੰਗ ਪ੍ਰਕਿਰਿਆਵਾਂ ਸਾਨੂੰ ਸ਼ਾਨਦਾਰ ਗੁਣਵੱਤਾ ਵਾਲੇ ਉਤਪਾਦ ਦੇ ਭਾਗਾਂ ਦੀ ਆਗਿਆ ਦਿੰਦੀਆਂ ਹਨ ਅਤੇ ਤੁਸੀਂ ਪਲਾਸਟਿਕ ਉਤਪਾਦ ਨੂੰ ਅਨੁਕੂਲਿਤ ਕਰਨ ਲਈ ਪ੍ਰੋਜੈਕਟ ਕਰਨ ਲਈ ਲੇਖਾ ਜੋਖਾ ਕਰ ਸਕਦੇ ਹੋ ...ਹੋਰ ਪੜ੍ਹੋ -

ਚੀਨ ਪਲਾਸਟਿਕ ਸਪਲਾਇਰ

ਪਲਾਸਟਿਕ ਦੀਆਂ ਮੁੱਖ ਸਮੱਗਰੀਆਂ ਅਤੇ ਵਿਸ਼ੇਸ਼ਤਾਵਾਂ ਆਮ ਪਲਾਸਟਿਕ ਸਾਰੇ ਕੁਦਰਤੀ ਪਦਾਰਥਾਂ ਜਿਵੇਂ ਕਿ ਸੈਲੂਲੋਜ਼, ਕੋਲਾ, ਕੁਦਰਤੀ ਗੈਸ, ਨਮਕ ਅਤੇ ਕੱਚੇ ਤੇਲ ਤੋਂ ਇੱਕ ਪੌਲੀਮੇਰਾਈਜ਼ੇਸ਼ਨ ਜਾਂ ਪੌਲੀਕੰਡੈਂਸੇਸ਼ਨ ਪ੍ਰਕਿਰਿਆ ਦੁਆਰਾ ਬਣਾਏ ਜਾਂਦੇ ਹਨ, ਅਤੇ ਇਹਨਾਂ ਦੋਵਾਂ ਨੂੰ ਖਾਸ ਉਤਪ੍ਰੇਰਕ ਦੀ ਲੋੜ ਹੁੰਦੀ ਹੈ।ਵਿੱਚ ਇੱਕ...ਹੋਰ ਪੜ੍ਹੋ -

ਇੱਕ ਵਿਸ਼ੇਸ਼ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡਿੰਗ ਸਮੱਗਰੀ - ਰੈਜ਼ਿਨ

ਉਤਪਾਦਾਂ ਦੇ ਵੱਧ ਤੋਂ ਵੱਧ ਵੰਨ-ਸੁਵੰਨਤਾ ਬਣਨ ਤੋਂ ਬਾਅਦ, ਸਾਡੀ ਕਲਾ ਵੀ ਸਧਾਰਨ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡਿੰਗ ਤੋਂ ਕਸਟਮ ਮੋਲਡਿੰਗ ਪ੍ਰਕਿਰਿਆਵਾਂ ਵਿੱਚ ਬਦਲ ਜਾਂਦੀ ਹੈ।ਅਤੇ ਸਾਨੂੰ ਟੀਕੇ ਦੀ ਪ੍ਰਕਿਰਿਆ ਵਿੱਚ ਇੱਕ ਵਿਸ਼ੇਸ਼ ਸਮੱਗਰੀ ਮਿਲੀ-ਰੇਜ਼ਿਨ, ਜੋ ਖਾਸ ਵਿਜ਼ੂਅਲ, ਕਾਸਮੈਟਿਕ, ਕਾਰਜਸ਼ੀਲ, ਤਾਕਤ, ਅਤੇ ਇੱਥੋਂ ਤੱਕ ਕਿ ... ਪ੍ਰਦਾਨ ਕਰ ਸਕਦੀ ਹੈ.ਹੋਰ ਪੜ੍ਹੋ -

ABS ਸਮੱਗਰੀ ਕੀ ਕਰ ਸਕਦੀ ਹੈ?

ਇੰਜੈਕਸ਼ਨ ਉਦਯੋਗ ਦੇ ਵਿਕਾਸ ਦੇ ਬਾਅਦ, ਏਬੀਐਸ ਸਮੱਗਰੀ ਨਿਰਮਾਣ ਨਾਲ ਵਧੇਰੇ ਪ੍ਰਸਿੱਧ ਹੋ ਗਈ ਹੈ.ਇੱਕ ਫੈਕਟਰੀ ਵਜੋਂ ਜੋ ਤੇਜ਼ ਪ੍ਰੋਟੋਟਾਈਪ, ਪਲਾਸਟਿਕ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡਿੰਗ, ਸਿਲੀਕੋਨ ਰਬੜ, ਸ਼ੀਟ ਮੈਟਲ, ਡਾਈ ਕਾਸਟਿੰਗ ਅਤੇ ਇਸਦੀ ਅਸੈਂਬਲੀ ਵੱਲ ਧਿਆਨ ਦਿੰਦੀ ਹੈ।RuiCheng ਤੁਹਾਨੂੰ ਪੇਸ਼ਕਸ਼ ਕਰ ਸਕਦਾ ਹੈ ਜਿਸ ਵਿੱਚ...ਹੋਰ ਪੜ੍ਹੋ -

ਪ੍ਰੋਫੈਸ਼ਨਲ ਮੈਡੀਕਲ ਡਿਵਾਈਸ ਨਿਰਮਾਤਾ- RuiCheng

ਸੰਖੇਪ ਜਾਣਕਾਰੀ ਭਾਗ ਦੀ ਸੁਰੱਖਿਆ ਅਤੇ ਸ਼ੁੱਧਤਾ ਮੈਡੀਕਲ ਉਦਯੋਗ ਲਈ ਮਹੱਤਵਪੂਰਨ ਹਨ। ਇੱਕ ਪੇਸ਼ੇਵਰ ਮੈਡੀਕਲ ਉਪਕਰਣ ਨਿਰਮਾਣ ਦੇ ਰੂਪ ਵਿੱਚ, RuiCheng ਟਿਕਾਊ ਅਤੇ ਮੈਡੀਕਲ-ਗਰੇਡ ਪਲਾਸਟਿਕ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡਿੰਗ ਹਿੱਸੇ ਪ੍ਰਦਾਨ ਕਰ ਸਕਦਾ ਹੈ, ਉਸੇ ਸਮੇਂ ਸਾਡੇ ਹਿੱਸੇ ਉਤਪਾਦ ਦੀਆਂ ਵਿਸ਼ੇਸ਼ਤਾਵਾਂ ਨੂੰ ਸੰਤੁਸ਼ਟ ਕਰ ਸਕਦੇ ਹਨ...ਹੋਰ ਪੜ੍ਹੋ -

TPU ਅਤੇ PC ਬਾਰੇ ਸਭ ਕੁਝ

ਜਦੋਂ ਤੁਸੀਂ ਸਾਡੀ ਵੈੱਬਸਾਈਟ ਰਾਹੀਂ, ਤੁਹਾਨੂੰ ਕੁਝ ਉਤਪਾਦ ਦੀ ਸਮੱਗਰੀ ਪੀਸੀ ਜਾਂ ਟੀਪੀਯੂ ਬਾਰੇ ਪਤਾ ਲੱਗ ਸਕਦੀ ਹੈ।ਪਰ, ਅਸਲ ਵਿੱਚ, PC/TPU ਕੀ ਹੈ?ਅਤੇ PC ਅਤੇ TPU ਨਾਲ ਕੀ ਵੱਖਰਾ ਹੈ?ਆਉ ਇਸ ਲੇਖ ਨਾਲ ਸ਼ੁਰੂ ਕਰੀਏ.ਪੀਸੀ ਪੌਲੀਕਾਰਬੋਨੇਟ (ਪੀਸੀ) ਥਰਮੋ ਦੇ ਇੱਕ ਸਮੂਹ ਨੂੰ ਦਰਸਾਉਂਦਾ ਹੈ ...ਹੋਰ ਪੜ੍ਹੋ -

ਟੀਕੇ ਲਈ ਓਵਰਮੋਲਡਿੰਗ ਬਾਰੇ ਗਾਈਡ

ਓਵਰਮੋਲਡਿੰਗ ਕਸਟਮ ਲਈ ਇੱਕ ਵਿਸ਼ੇਸ਼ ਇੰਜੈਕਸ਼ਨ ਤਕਨਾਲੋਜੀ ਹੈ, ਹੁਣ ਓਵਰਮੋਲਡਿੰਗ ਉਤਪਾਦਾਂ ਦੀ ਕਾਰਜਕੁਸ਼ਲਤਾ, ਪ੍ਰਦਰਸ਼ਨ ਅਤੇ ਬਾਹਰੀ ਰੂਪ ਵਿੱਚ ਸੁਧਾਰ ਕਰਦੀ ਹੈ, ਜੋ ਇਸਨੂੰ ਉਪਭੋਗਤਾ ਉਤਪਾਦਾਂ, ਮੈਡੀਕਲ ਡਿਵਾਈਸਾਂ ਅਤੇ ਪੋਰਟੇਬਲ ਡਿਵਾਈਸਾਂ ਦੇ ਨਿਰਮਾਤਾਵਾਂ ਵਿੱਚ ਵਧੇਰੇ ਪ੍ਰਸਿੱਧ ਬਣਾਉਂਦੀ ਹੈ।ਪਰ ਓਵਰਮੋਲ ਕੀ ਹੈ ...ਹੋਰ ਪੜ੍ਹੋ -

ਐਬਸ ਇਲੈਕਟ੍ਰੋਪਲੇਟਿੰਗ ਕੀ ਹੈ

ਇਲੈਕਟ੍ਰੋਪਲੇਟਿੰਗ ਬਾਰੇ ਸੰਖੇਪ ਜਾਣਕਾਰੀ ਉਦਯੋਗ ਵਿੱਚ, ਅਸੀਂ ਅਕਸਰ ਮੈਟਲ ਇਲੈਕਟ੍ਰੋਪਲੇਟਿੰਗ ਜਾਂ ਇਲੈਕਟ੍ਰੋਪਲੇਟਿੰਗ ਕਰਾਫਟ ਬਾਰੇ ਸੁਣਦੇ ਹਾਂ। ਪਰ ਕੀ ਤੁਸੀਂ ਅਸਲ ਵਿੱਚ ਇਲੈਕਟ੍ਰੋਪਲੇਟਿੰਗ ਬਾਰੇ ਜਾਣਦੇ ਹੋ ਅਤੇ ਉਤਪਾਦਾਂ ਨੂੰ ਬਿਹਤਰ ਬਣਾਉਣ ਲਈ ਇਸਦੀ ਵਰਤੋਂ ਕਿਵੇਂ ਕਰਨੀ ਹੈ?ਇਹ ਲੇਖ ਸਪਸ਼ਟ ਤੌਰ 'ਤੇ ਇਲੈਕਟ੍ਰੋਪਲੇਟਿੰਗ ਬਾਰੇ ਜਾਣਕਾਰੀ ਪੇਸ਼ ਕਰੇਗਾ ...ਹੋਰ ਪੜ੍ਹੋ -

ਆਟੋਮੋਟਿਵ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡ ਪਾਰਟਸ ਦੀ ਪੇਸ਼ੇਵਰ ਅਨੁਕੂਲਤਾ

ਜਿਵੇਂ ਕਿ ਅਸੀਂ ਸਾਰੇ ਜਾਣਦੇ ਹਾਂ ਕਿ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡਿੰਗ ਪਲਾਸਟਿਕ ਲਈ ਸਭ ਤੋਂ ਵੱਧ ਵਰਤੀਆਂ ਜਾਣ ਵਾਲੀਆਂ ਉਤਪਾਦਨ ਪ੍ਰਕਿਰਿਆਵਾਂ ਵਿੱਚੋਂ ਇੱਕ ਹੈ, ਇਸ ਲਈ ਜਦੋਂ ਅਸੀਂ ਆਟੋਮੋਬਾਈਲ ਦੇ ਬਹੁਤ ਸਾਰੇ ਗੁੰਝਲਦਾਰ ਹਿੱਸੇ ਬਣਾਉਂਦੇ ਹਾਂ ਤਾਂ ਆਮ ਤੌਰ 'ਤੇ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡਿੰਗ ਪ੍ਰਕਿਰਿਆਵਾਂ ਦੀ ਵਰਤੋਂ ਕੀਤੀ ਜਾਂਦੀ ਹੈ।ਇਸ ਲੇਖ ਵਿਚ, ਅਸੀਂ ਪਲਾਸਟਿਕ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡਿੰਗ ਦੀ ਵਰਤੋਂ 'ਤੇ ਡੂੰਘੀ ਵਿਚਾਰ ਕਰਾਂਗੇ.ਇਸ ਵਿੱਚ...ਹੋਰ ਪੜ੍ਹੋ -

ਇੰਜੈਕਸ਼ਨ ਮੋਲਡ ਕੀਤੇ ਹਿੱਸਿਆਂ 'ਤੇ ਗੁਣਵੱਤਾ ਨਿਯੰਤਰਣ

ਇੰਜੈਕਸ਼ਨ ਮੋਲਡਿੰਗ ਪ੍ਰਕਿਰਿਆ ਦੇ ਦੌਰਾਨ, ਮੋਲਡ ਕੀਤੇ ਹਿੱਸਿਆਂ ਵਿੱਚ ਵੱਖ-ਵੱਖ ਨੁਕਸਾਂ ਦਾ ਸਾਹਮਣਾ ਕਰਨਾ ਆਮ ਗੱਲ ਹੈ, ਜੋ ਉਤਪਾਦਾਂ ਦੀ ਗੁਣਵੱਤਾ ਅਤੇ ਪ੍ਰਦਰਸ਼ਨ ਨੂੰ ਪ੍ਰਭਾਵਤ ਕਰ ਸਕਦੇ ਹਨ।ਇਸ ਲੇਖ ਦਾ ਉਦੇਸ਼ ਇੰਜੈਕਸ਼ਨ ਮੋਲਡ ਕੀਤੇ ਹਿੱਸਿਆਂ ਵਿੱਚ ਕੁਝ ਆਮ ਨੁਕਸਾਂ ਦੀ ਪੜਚੋਲ ਕਰਨਾ ਅਤੇ ਹੱਲ ਕਰਨ ਦੇ ਤਰੀਕਿਆਂ ਬਾਰੇ ਚਰਚਾ ਕਰਨਾ ਹੈ...ਹੋਰ ਪੜ੍ਹੋ -

ਪਲਾਸਟਿਕ ਕੰਪੋਨੈਂਟਸ ਲਈ ਮੋਲਡ ਡਿਜ਼ਾਈਨ ਅਤੇ ਨਿਰਮਾਣ

ਪਲਾਸਟਿਕ ਕੰਪੋਨੈਂਟਸ ਲਈ ਮੋਲਡ ਡਿਜ਼ਾਈਨ ਅਤੇ ਨਿਰਮਾਣ: ਅਨੁਕੂਲਨ ਤਕਨੀਕਾਂ ਅਤੇ ਨਵੀਨਤਾਕਾਰੀ ਹੱਲ ਉਦਯੋਗਿਕ ਡਿਜ਼ਾਈਨ ਦੇ ਖੇਤਰ ਵਿੱਚ, ਪਲਾਸਟਿਕ ਦੇ ਹਿੱਸਿਆਂ ਦਾ ਡਿਜ਼ਾਈਨ ਅਤੇ ਮੋਲਡਾਂ ਦਾ ਨਿਰਮਾਣ ਮਹੱਤਵਪੂਰਨ ਪੜਾਅ ਹਨ।ਇਹ ਲੇਖ ਡਿਸਕ ਕਰੇਗਾ...ਹੋਰ ਪੜ੍ਹੋ